How Loop Powered Isolators Work

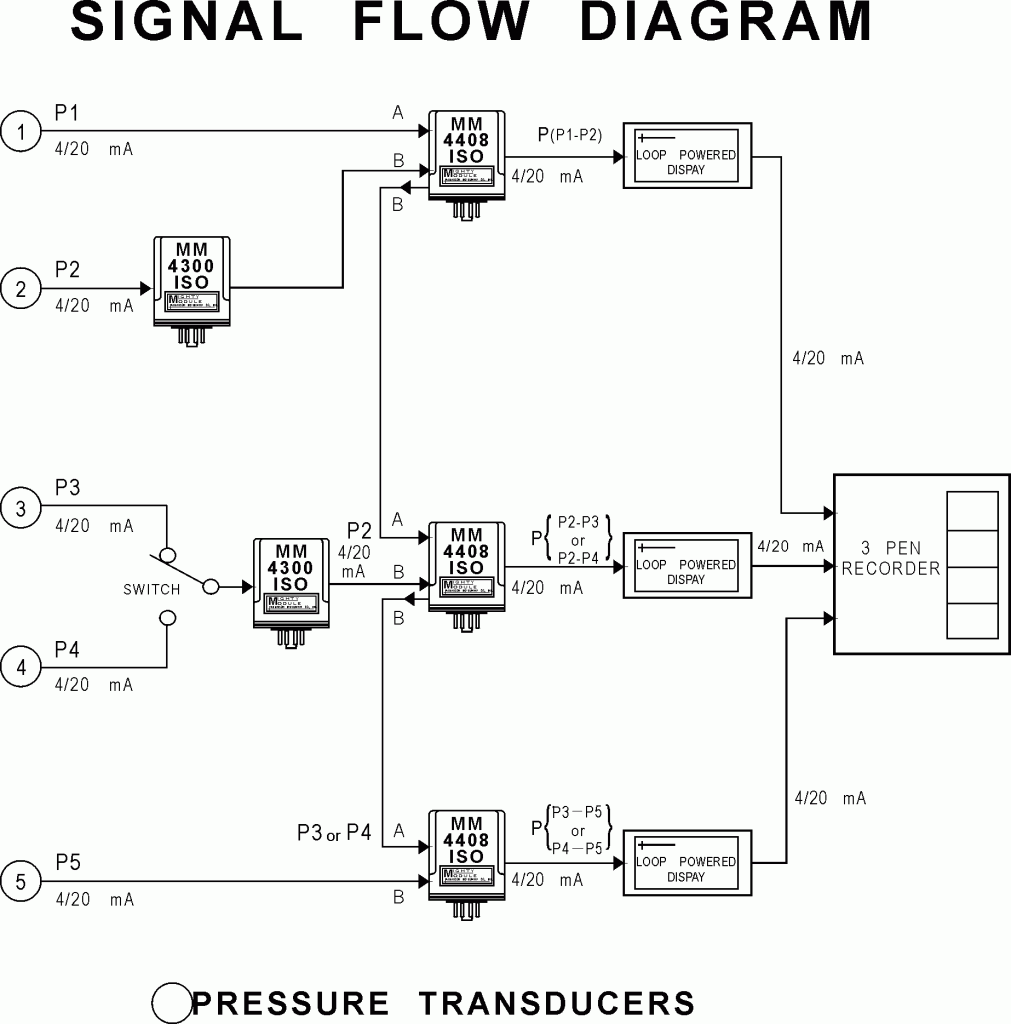

Loop powered isolators are necessary when an extra isolated 4/20mA output is required in areas where no power is available.

A loop powered isolator’s power is provided by its 4/20mA input current. This makes it possible for an existing 4/20mA loop to be used to provide another isolated 4/20mA output through a loop powered isolator.

A loop powered isolator is basically a center tapped transformer which has the input 4/20mA current flowing through its center tap on the primary. An oscillator circuit alternately switches the current through each half of the primary. This alternating current creates a current in the secondary of the transformer. The voltage out of the secondary is rectified and filtered.

The turns ratio on the transformer is designed with a slight step down so the current out of the secondary is slightly greater than the input current.

This is a simple form of a loop power isolator, but it has shortcomings in that the transformer is not perfectly linear over the current range. The current is also sensitive to the load resistance on the secondary.

A more complex version of a loop powered isolator has basically the same transformer circuit, but it has a circuit which monitors the current into the unit. The circuit passes this data through another isolation circuit to the secondary side of the unit. This circuit controls the current out of the isolator so it exactly matches the input current. This control circuit makes the loop powered isolator as accurate and linear as any powered transmitter.The DM4391 utilizes this feed forward circuit to provide an accurate and linear 4/20mA output.

The DM4391 can be connected anywhere in an existing 4/20mA loop. It is available as a single channel or dual channel unit.

For specifications and information about the DM4391 see our Catalog Page (pdf) or Installation / Operation Manual (pdf)